- Top: 62Step on: 4134

owens corning cool roof system

People involved | Date:2025-08-16 10:03:36

Related articles

The ongoing investments in infrastructure and technology by global trade networks indicate a bright future for container handlers. These machines will remain key elements in achieving the efficiency and speed required to succeed in a competitive and ever-changing marketplace.

The Importance of Welding Fume Management

Choosing the Right System

The adoption of robotic welding arms offers numerous advantages for manufacturers looking to improve their processes

In recent years, automatic spray painting technology has gained significant traction across various industries, from automotive manufacturing to furniture production. This innovation not only enhances efficiency and consistency but also revolutionizes traditional painting methods. As industries continue to adapt to automation and advanced technologies, automatic spray painting stands out as a key player in driving productivity and quality.

By integrating automatic spray painting robots with cutting-edge technologies like AI-driven adjustments, manufacturers can achieve unparalleled control over the painting process. This flexibility ensures that businesses can adapt to evolving market demands and maintain a competitive edge.

Ultimately, the integration of automated spray coating systems into production lines is not a mere operational upgrade but a strategic investment that correlates to improved bottom lines. Their implementation requires an understanding of system capabilities and operational requirements. Businesses must conduct a thorough analysis of their production needs, system compatibility, and the expertise required to operate these sophisticated machines. As manufacturing industries move towards greater automation, those who master the intricacies of automated spray coating systems will not only lead in efficiency and quality but set the standard for modern manufacturing practices.

- Airless Spray Utilizing high pressure to atomize the paint, this method is often used for thicker materials and large surface areas, making it ideal for industrial applications.

Automatic paint dispensers stand as a testament to how technology can enhance traditional practices, offering unmatched convenience, consistency, and outcomes. Their growing popularity is no surprise, as they embody the perfect blend of cutting-edge technology and user-focused design, catering to a broad spectrum of painting needs. Whether for a seasoned professional or a weekend DIY warrior, incorporating an automatic paint dispenser into your toolkit signifies a step towards efficiency and excellence in painting projects.

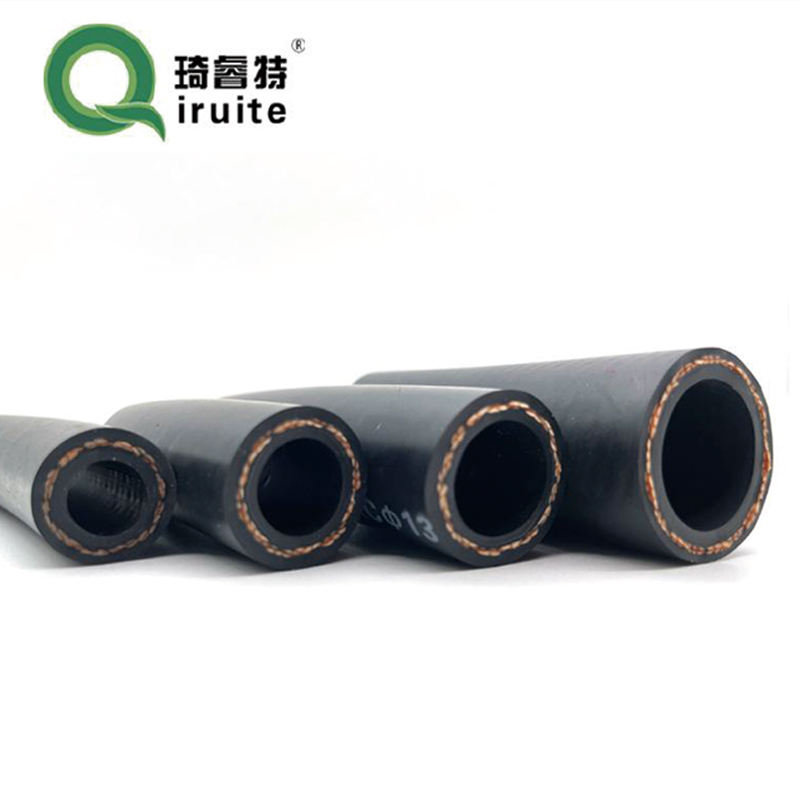

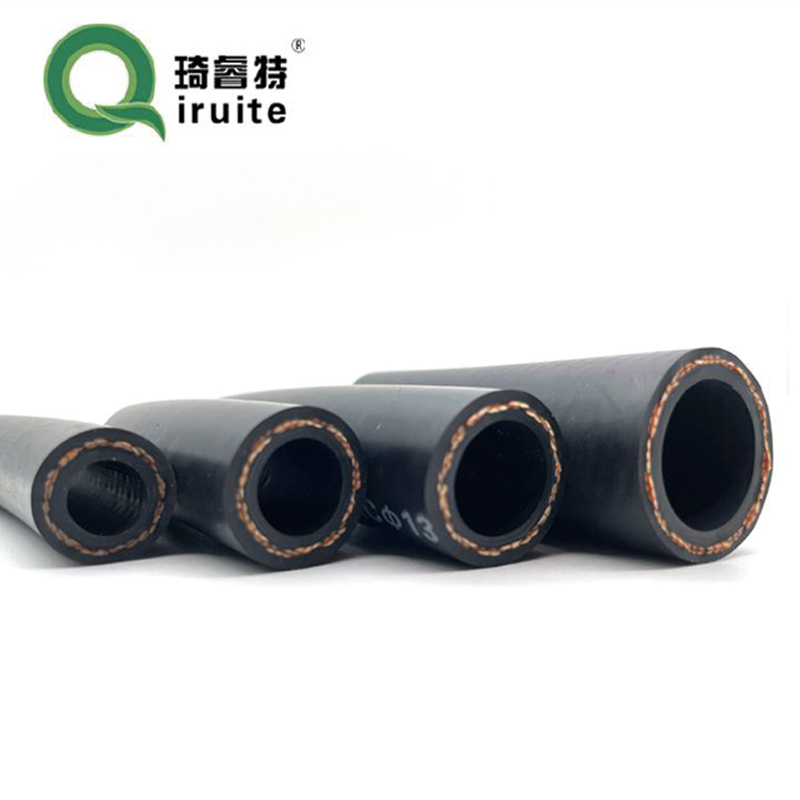

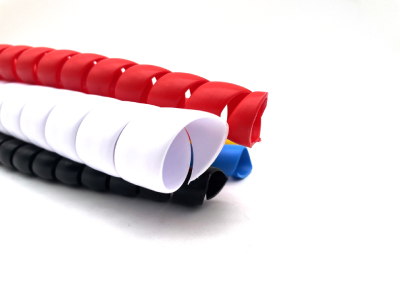

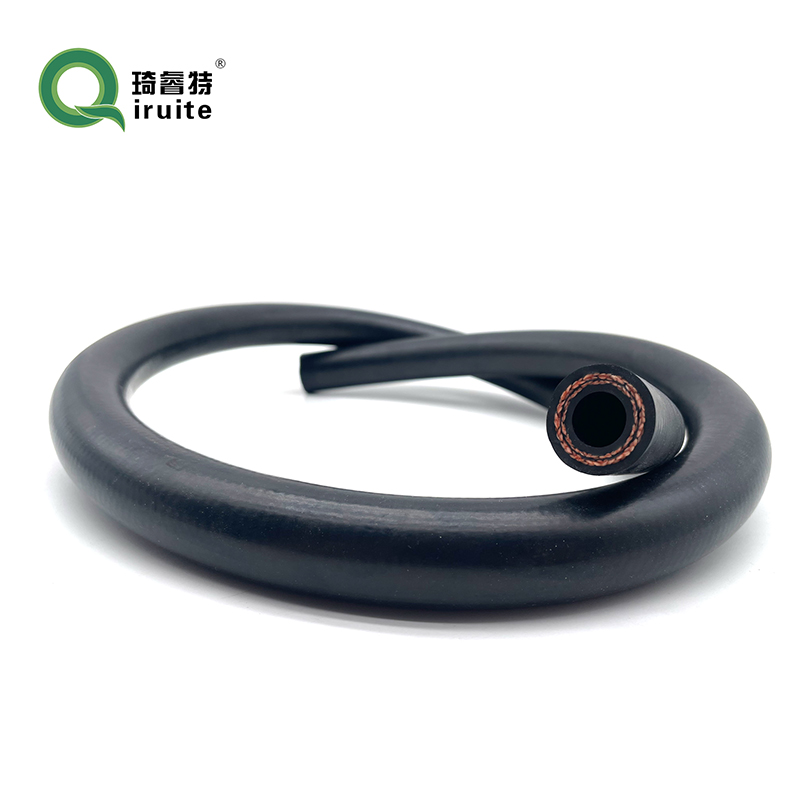

This hose often runs along the passenger side firewall and can be secured with tie wraps or clamps to prevent vibrations and wear This hose often runs along the passenger side firewall and can be secured with tie wraps or clamps to prevent vibrations and wear

This hose often runs along the passenger side firewall and can be secured with tie wraps or clamps to prevent vibrations and wear This hose often runs along the passenger side firewall and can be secured with tie wraps or clamps to prevent vibrations and wear Regular maintenance, including visual inspections and timely repairs, is vital to catch any potential issues before they escalate into major problems Regular maintenance, including visual inspections and timely repairs, is vital to catch any potential issues before they escalate into major problems

Regular maintenance, including visual inspections and timely repairs, is vital to catch any potential issues before they escalate into major problems Regular maintenance, including visual inspections and timely repairs, is vital to catch any potential issues before they escalate into major problems

Regular Inspection It is essential to inspect the Gates 1-inch power steering hose regularly for any signs of damage, such as cracks, leaks, or swelling Regular Inspection It is essential to inspect the Gates 1-inch power steering hose regularly for any signs of damage, such as cracks, leaks, or swelling

Regular Inspection It is essential to inspect the Gates 1-inch power steering hose regularly for any signs of damage, such as cracks, leaks, or swelling Regular Inspection It is essential to inspect the Gates 1-inch power steering hose regularly for any signs of damage, such as cracks, leaks, or swelling

Comment area